Because 2020, a multitude of interruptions has actually blocked the smooth operations of business all over the world, making it hard for numerous to acquire the parts they require or get their items to consumers. With substantial financial unpredictability most likely to continue in the foreseeable future, magnate would be a good idea to prepare their business to adjust quicker and holistically to altering conditions.

Based upon my substantial experience as a company preparation and company operations expert, I think that the very best method to do this is through sales and operations preparation (S&OP). There are various methods to execute this collective approach, however they all assist business establish a detailed long-lasting strategy (12 to 18 months) that consists of and lines up particular goals for both the business departments (item, sales, and customer support) and operations. I typically suggest likewise consisting of financing (monetary preparation, budgeting, and expense management) and worldwide method departments when carrying out S&OP, an approach often called incorporated company preparation (IBP).

S&OP is an iterative procedure, so it routinely integrates brand-new input from stakeholders, making it possible for a business to react quickly to altering environments. And among the chief advantages of my technique is that it can sync supply with customer need, while at the same time matching everyday operations to company goals

Business that continuously utilize brand-new details to adjust can find approaching issues prior to they strike. For instance, S&OP can signal companies that they might require to recognize alternative makers, suppliers, or suppliers to utilize when their routine partners can’t provide items. A couple of years back, I was dealing with a vehicle parts business in Ecuador that purchased items to disperse to consumers. We began having issues getting the parts from our suppliers, which were based in China. However in the course of S&OP work, we had actually currently looked into backup suppliers and discovered a parts supplier in Dubai. When barriers appeared, we rotated promptly to get the items from this brand-new source and decreased any influence on our consumers.

Research study recommends that our experience was not special. According to evaluations of more than 170 business by McKinsey & & Business, companies with a well-functioning IBP execution have “service levels that are 5 to 20 portion points greater, freight expenses and capital strength (overall possessions divided by sales) that are 10% to 15% lower, and consumer shipment charges and missed out on sales that are 40% to 50% lower” than those of business without reliable IBP. Companies that have actually enhanced IBP procedures are 10% to 20% more efficient than companies without them, and they react to disruptive occasions rapidly and efficiently.

While S&OP is not a brand-new procedure, the supply chain crisis has actually made it clear that too couple of business are taking advantage of it, either since they do not have the ideal procedures in location, or they aren’t utilizing them to finest result. In this post, I share my insights about how to start or enhance S&OP execution so your business can weather supply chain issues and other prospective interruptions, like freight or freight container constraints, natural catastrophes, or IT failures.

Why S&OP Optimization Is So Crucial Now

I was presented to S&OP more than twenty years ago while establishing a producing resource preparation procedure for a cosmetics maker. At that time, S&OP was a practical method to keep positioning on business objectives and to increase efficiency and minimize waste when particular issues developed that were exceptions to the standard. Today, in the consequences of a generalized worldwide supply chain crisis, S&OP has actually ended up being a requirement for companies that count on several supply chain procedures

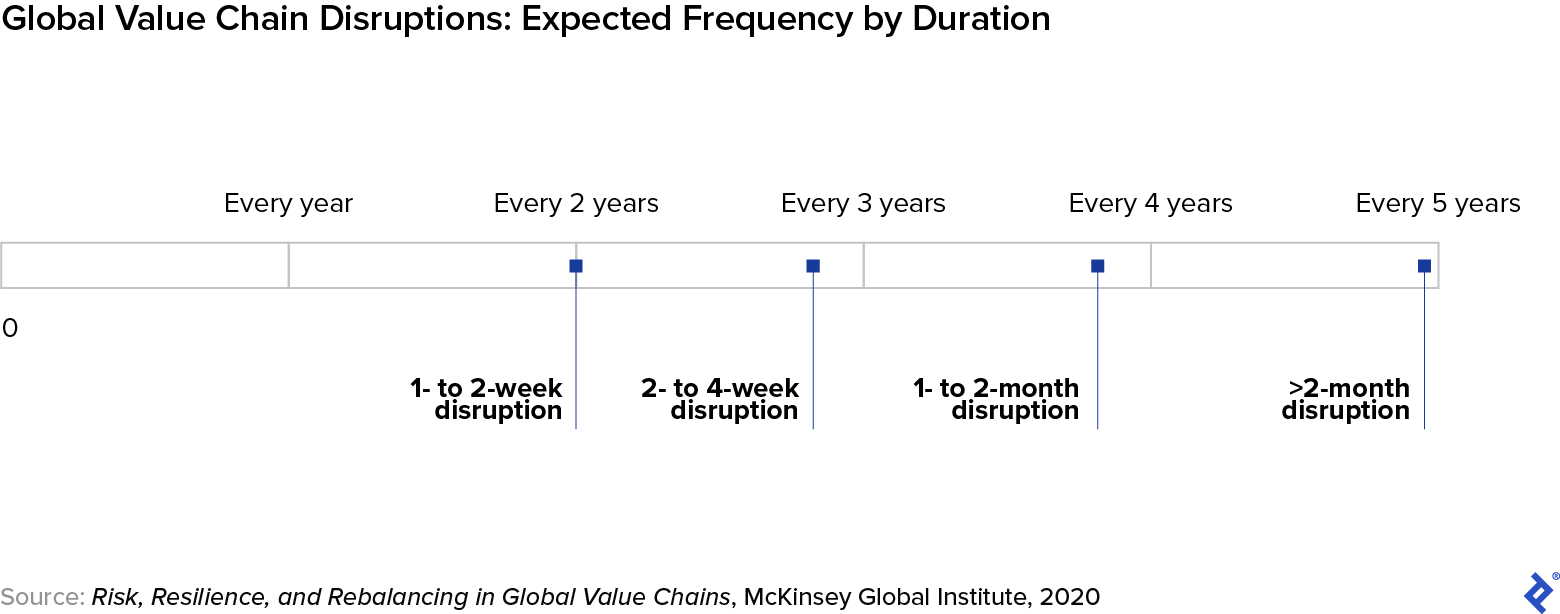

By now, the worldwide supply chain interruptions triggered by the COVID-19 pandemic, the Russia-Ukraine dispute, escalating freight shipping costs, minimal shipping container supply, and other aspects have actually mainly decreased. Nevertheless, there are constantly unknowns on the horizon. A McKinsey Global Institute report discovered that business must “anticipate supply chain interruptions lasting a month or longer to take place every 3.7 years” which the collected losses of these occasions might represent 42% of one year’s earnings over a 10-year duration.

Today’s long, complicated supply chains are extremely susceptible to interruptions, consisting of severe weather condition occasions, terrorism, or trade conflicts. That’s why S&OP is so crucial. In reality, enhancing S&OP is the leading concern for primary supply officers, according to a 2020 study by The Hackett Group, and continues to be an essential centerpiece for optimization. This issue is an indirect recognition that put simply a procedure in location isn’t enough. Badly performed S&OP can likewise disrupt a company’s capability to get alternate makers, suppliers, and suppliers; recognize alternative consumers; or typically handle its market and need.

Business have actually constantly been worried about unforeseen occasions that might make it hard for them to get the products they require, produce sufficient to fulfill need, or get their items to their consumers. However for today’s hyperproductive companies, usually counting on an extremely vulnerable worldwide worth chain, the stakes are greater than ever previously.

How the S&OP Process Functions

Initially, let’s take a look at how S&OP is developed to operate. It’s an extremely collective procedure that includes input from every department at every phase. Preliminary execution begins with the development of a cross-functional S&OP group that works to collaborate and complete strategies at each phase. While your group’s specific structure will differ based upon your business’s size and makeup, with the IBP technique, it typically consists of individuals from the following departments:

- Commercial: item, sales, and customer support supervisors, need supervisor, and need coordinators

- Operations: production master scheduler, supply chain coordinators, purchasers, quality control professionals, and circulation supervisors

- Financing: controller, costing accounting professional, and monetary preparation supervisor or budgeting supervisor

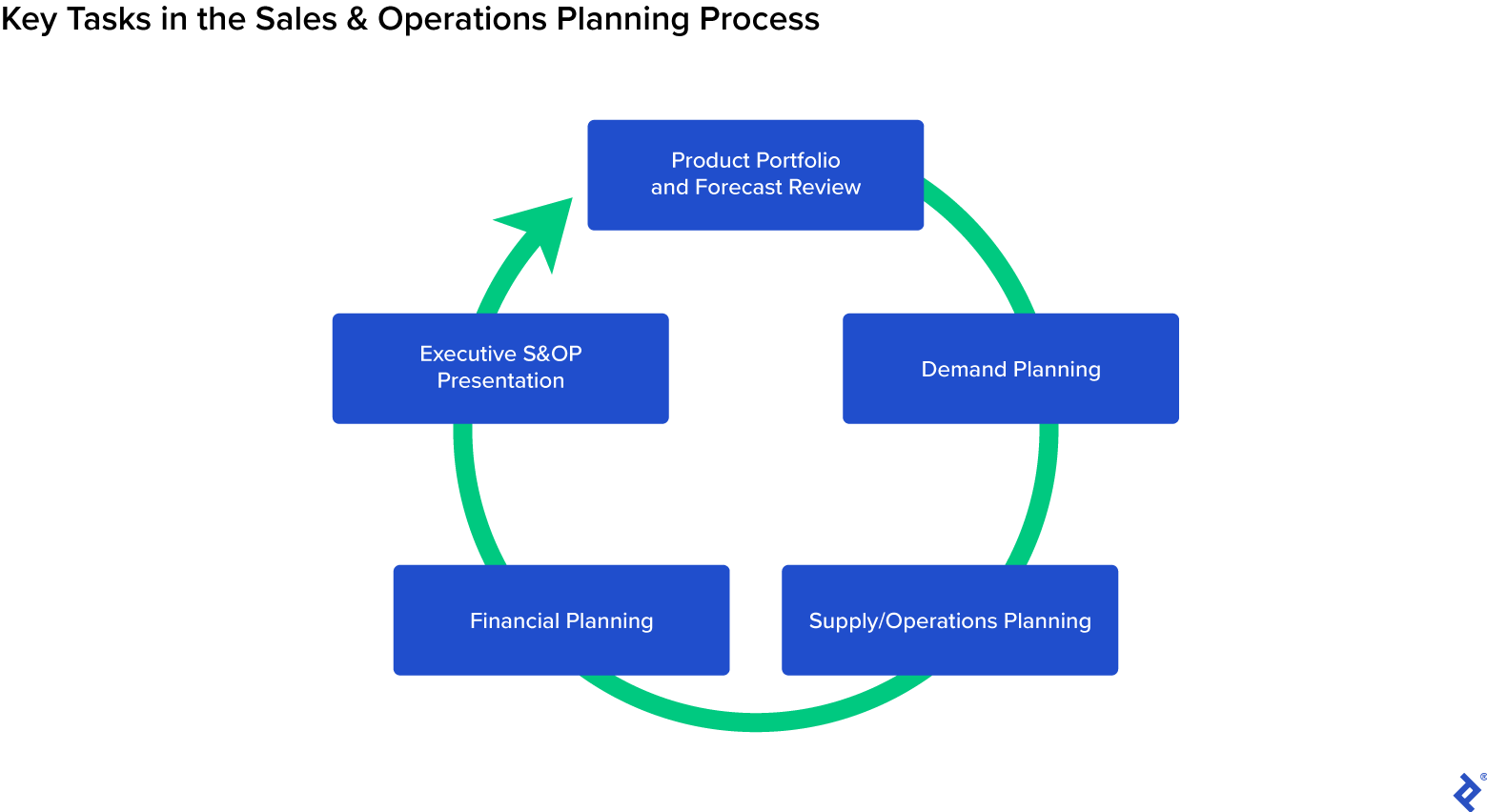

No matter who is on your S&OP group, the primary actions in the procedure must be the very same.

Core Actions In the S&OP Process

For appropriate S&OP execution, you’ll require to achieve– and repeat– all of these actions, however you can adjust them for your company. For instance, if among these conferences ends up being too long or complex, you can divide it into 2 more-manageable ones. On the other hand, if a couple of conferences appear short, you can integrate them into one session.

- Item portfolio and projection evaluation: This action intends to provide a unified business item method by evaluating the life process of each product in the business item portfolio. In order for the S&OP group to see an incorporated evaluation of each service or product that will go to market and be used to consumers, all departments associated with the S&OP procedure contribute information, like previous sales history and sales projections, stock, production capability, forecasted need, and external occasions that might impact need. The action likewise takes into consideration the most current monetary information, such as production expenses, cost, margins, holding expenses, transport expenses, and so on. Considering that S&OP is an iterative procedure, after the very first time through, the strategy gotten in the last S&OP executive discussion is likewise incorporated into this item evaluation.

- Need preparation: The objective of this action is to guarantee your business’s resources and sales objectives are lined up, so that your production and supply chain can produce the stock to fulfill expected consumer need immediately. This procedure utilizes previous need patterns and projections to forecast requirement for product or services throughout the supply chain. Historic sales information, market patterns, and other pertinent details from the various departments are examined to approximate just how much of a product and services will be needed. Input and feedback from the operations group are particularly crucial here so that you can specify reasonable need levels according to item accessibility. The resulting need strategy is likewise examined and changed by the S&OP group to keep it lined up with tactical business objectives like line of product development, discount rate portion, and gross margins.

- Supply/operations preparation: Next, the need strategy is equated into a supply strategy, so that stock and products are offered to support the forecasted need. A few of the jobs here consist of forecasting need for basic materials, parts, and other inputs; determining and evaluating prospective providers; keeping track of provider efficiency; determining and evaluating prospective threats to the supply chain (like freight constraints, provider interruptions, or modifications in market conditions), and establishing strategies to alleviate these threats; and ensuring that the supply strategy lines up with business concerns, such as stock levels, resource usage, fill rates, and portion of best orders

- Monetary preparation: Based upon the need and supply/operations strategies, the monetary group’s strategy takes a look at the anticipated need for a product and services and the associated expenses to approximate the business’s monetary efficiency over a particular duration. The primary deliverables here are the forecasted P&L declaration, the forecasted capital declaration, and the spending plan compliance report. Expense is examined as a secondary issue. The cross-functional S&OP group evaluations and talks about the strategy along with the need and supply strategies to see that the business’s monetary objectives are lined up with its functional objectives which the business has the resources it requires to fulfill need and attain its monetary objectives.

- Executive S&OP discussion: Next, the S&OP group provides the bottom lines of the overarching strategy to senior management to get executive input, approval, and buy-in. Generally, the group and management likewise think about “what if” situations to make choices and last strategy changes. Then the S&OP group integrates suggestions from senior management and evaluates the outcomes prior to continuing. The primary deliverable of this conference is a detailed, integrated strategy that lines up with the business’s tactical, functional, and monetary goals. This strategy will likewise notify the initial step of the next duration’s S&OP.

This S&OP cycle is typically duplicated monthly, permitting stakeholders to remain lined up while continuously improving the long-lasting strategy based upon modifications to company requirements, the supply chain, or market conditions. And because the daily activities of every department link straight to the long-lasting strategy, every one can act promptly to resolve unpredicted scenarios. Any modifications in requirements or scenarios, consisting of brand-new or modified restrictions, must be interacted right away to the whole S&OP group. Having a long-lasting strategy that’s modified typically likewise assists your business reach contracts with tactical suppliers and consumers, boost company responsiveness, and secure margins.

5 Tips for S&OP Success

Throughout my 25 years in the field, I have actually seen 5 execution problems regularly hamper effective S&OP. These are the very best practices your company must follow in order to enjoy the complete advantages of S&OP:

Collaborate Constantly

Numerous business see the S&OP procedure as linear: The business group provides a need requirement, and the operations group creates enough stock to support it. This technique will not enhance company responsiveness. Rather, you need to get all individuals on the multidisciplinary S&OP group to collaborate– not sequentially– from the start. The business group requires to interact with operations while establishing its need strategy so operations can begin producing stock. Also, operations needs to speak to the financing group to figure out just how much stock the business can pay for to produce.

This sort of interlacing partnership isn’t an offered. When I began dealing with the regional workplace of a big food production and processing corporation in 2005, the business didn’t have a devoted S&OP group or an efficient procedure. Although the business department provided a regular monthly need strategy, operations constantly modified it prior to establishing its own strategy– without sharing it with commercial. So there were 2 various strategies running in parallel.

When I enhanced S&OP at this business, the group I formed begun doing unbiased historic information analysis and utilized the insights we collected to fix the preliminary strategy. The outcome? A combined, effective strategy that increased efficiency, cut costs, and decreased losses. At last, operations was spending for the level of producing that fit the business group’s marketing methods– and the financing group had the capital to support them. Once they saw these advantages, the departments were more happy to team up with one another, making subsequent preparation quicker and easier.

Bring Management on Board

Having a CEO or basic supervisor who’s not completely dedicated to the strategy set by the S&OP group substantially compromises the procedure’s efficiency. S&OP aims to bring and keep all departments in positioning. If a CEO isn’t knowledgeable about the procedure or does not completely comprehend it and sets a various instructions, subordinates will need to follow. At finest, the business’s effort will be fragmented; at worst, the departments will be operating at cross functions. Yet, executives’ decision-making is typically not lined up with S&OP since they consider it an optional addition, not as a system completely incorporated into their daily conferences and operations.

When I executed S&OP in a big cosmetics corporation in Latin America, my very first relocation was to sit with the basic supervisor of among business systems to go over the actions included. The supervisor currently had a regular monthly committee conference with his senior personnel, so he didn’t like the concept of an “additional” visit. I recommended combining the conferences and evaluating the primary company KPIs and problems together with the S&OP strategy. Our very first session lasted more than 10 hours. However it revealed the GM the approach’s advantages, and he authorized its usage for the business. He assisted specify the strategy, consented to handle it, and provided the group genuine assistance. In time, the executive S&OP conference was reduced to less than 3 hours.

Demand Responsibility

At every business, an S&OP procedure needs both the everyday execution of jobs with due dates and a transparent chain of duties. Every individual needs to be liable for the tasks they accept. Responsibility ought to be an offered, however I have actually seen numerous business overlook it. And the worst circumstance an S&OP group can deal with is recognizing the strategy stopped working since someone didn’t finish a job.

Instead of allow failures, senior management needs to hold all S&OP staff member liable. For that to work, duties need to be plainly specified. Specific tasks need to be defined and tracked, and there must be effects for not satisfying tasks– along with rewards for prospering. One method to achieve this is to connect revenues to efficiency.

Shut Off the Sound

For S&OP to operate well, focus is crucial. In numerous executions I have actually dealt with, staff member waste excessive time evaluating historic outcomes, typically since they’re arguing and attempting to validate their choices or appointing blame for previous failures. Historic outcomes must just be points of recommendation for constant enhancement of the S&OP procedure. My basic guideline: Your group should invest one-third of its time taking a look at the past and two-thirds specifying and evaluating its prepare for the future.

Another sort of sound is bad information quality or management Examples of this consist of information that’s irregular throughout departments, along with absence of clearness about information meanings and preparation. At its very first conference, your S&OP group must specify, concur upon, and carry out an official approach for getting, unifying, and providing details. In this manner, you can rapidly make choices based upon information all departments trust, assisting the business pivot even in the face of an industry-changing disturbance.

Keep Info Flowing

Business can just respond as rapidly as their interaction channels and practices enable. Based upon my observations, companies that reacted efficiently to COVID-19-related supply chain constraints collected and moved details promptly throughout their companies as they made collective choices. Commercial, functional, and monetary departments likewise require strong interaction procedures to remain in positioning as they react to crises. This indicates having conferences a minimum of when a week and sharing updates and details daily.

I saw the results of insufficient interaction at the food business I pointed out previously. The business and functional departments didn’t share details regularly and didn’t follow a unified strategy. Operations didn’t understand the business group’s sales volume, so it created excessive item. As a result, the business had out of balance stock levels and big volumes of item scrap due to expiration, significance losses of near $1 million. To tackle this problem, I established an Excel spreadsheet that carried out first-expired, first-out stock management with an offered projection and stock. This created cautions that triggered operations to recommend changes to the quotes, letting the business group develop promos for at-risk items. Weekly conferences in between groups reinforced this procedure, and the S&OP group minimized item write-offs by 80% in one year.

Info like stock levels of at-risk items can’t wait. To increase responsiveness, business must carry out not just the regular monthly S&OP cycle interaction however likewise great interaction practices for daily performance, which some companies call sales and operations execution (S&OE).

Enhanced S&OP execution assists your business prepare for and resolve issues rapidly and effectively. The long-lasting preparation included enhances your capability to alleviate interruptions to your supply chains or other networks, while the focus on routine evaluation and modification keeps company as typical a concern. And while the preliminary setup might need time, believed, and effort, this procedure will enable your business to react adroitly to whatever comes at it. You can’t stop modification– however you can be all set to fulfill it.